MATISA tamping machine tools are designed for excellence. They meet the highest levels in terms of track geometry accuracy and ballast compaction quality. MATISA has a long tradition in manufacturing compact, strong and efficient tools; they cover a wide range of applications while ensuring exceptional performance and constant results. MATISA stands for solutions that are both proven and exclusive, such as the high frequency elliptical tamping technology or the modular profile brushing. With their very low maintenance costs, these tools keep maintenance times, and therefore machine downtimes, to a strict minimum.

The tamping machines are equipped with tools for correcting the geometry and tamping the sleepers. To meet your specific needs and application requirements, your tamping machine can be fitted with additional tools such as brushes, ballast profiling ploughs or ballast compaction tools. Equipped in such a way, your MATISA tamping machine will be ready for the most demanding situations and will meet all your expectations regarding work performance and quality, as well as ease of use and flexibility.

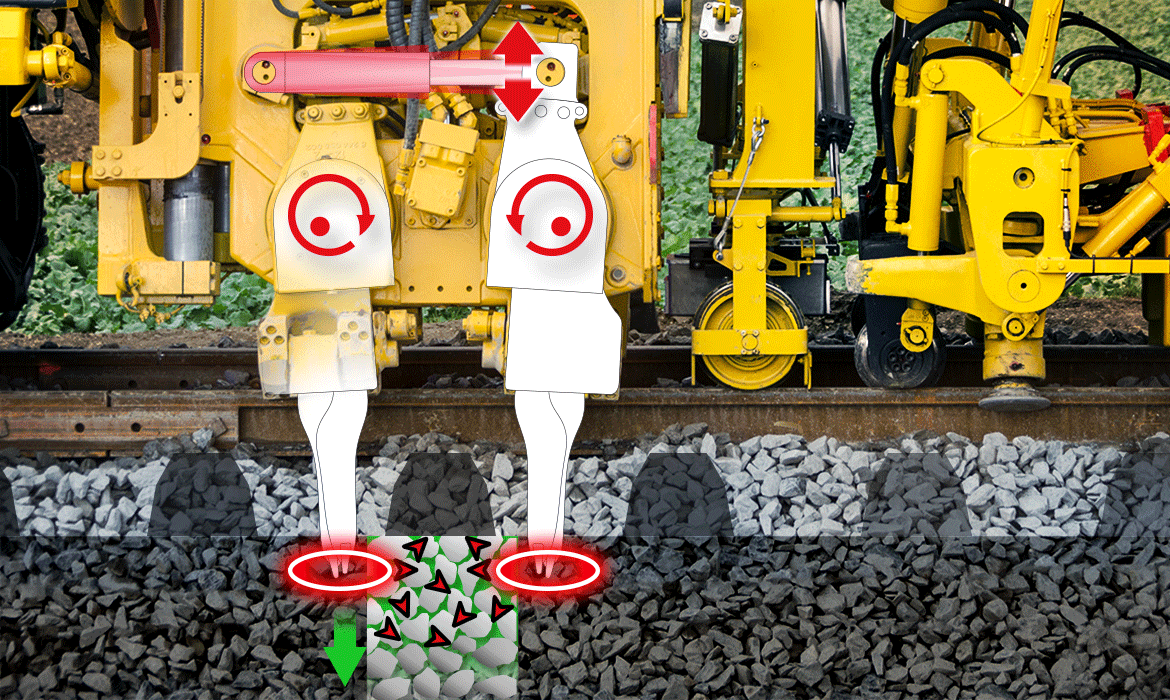

MATISA has a worldwide unique tamping technology achieving exceptional results. Ballast compaction quality is incomparable thanks to the high frequency elliptical movement tamping units which have the following features:

The high frequency elliptical tamping technology ensures very efficient ballast compaction, even with only small track lifting corrections. The volume of compacted ballast is relatively substantial, thus giving a good anchorage of the sleepers.

The C type combined tamping units represent the state-of-the-art in terms of switches and crossings tamping technology. Each unit has four tamping tools; two of them can be overlaid. In addition, the processing time for a switch is shortened thanks to the many advantages of these units:

Performance in plain line is also outstanding. Tamping units fitted with consequent longitudinal movements can easily and quickly work on tracks with Y shaped sleepers. These units are also known for their longevity, their reliability and their reduced maintenance costs.

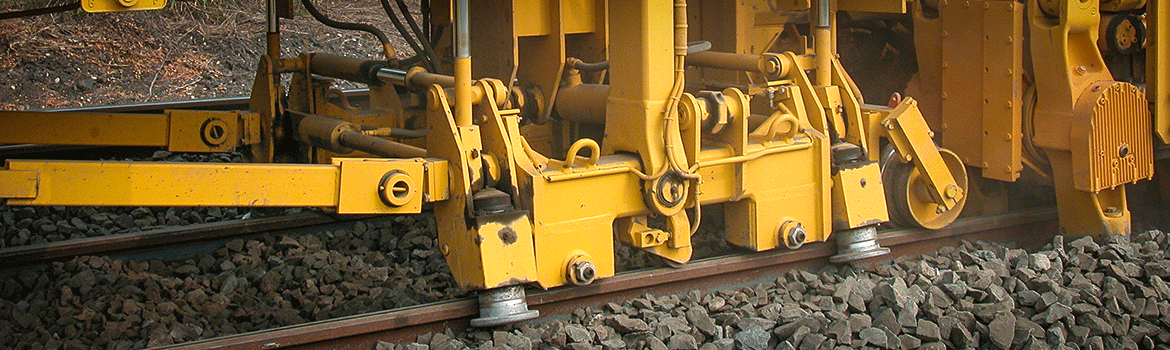

The D type double-head tamping units for plain line tamp two sleepers at a time.

Each unit has 16 tamping tools and two single-double sleeper opening devices. The machines fitted with these units have a total of 32 tamping tools, enabling a high output.

These heavy units feature fully independent tamping tool arms and very easy tamping tool penetration into the ballast, ensuring a very high tamping quality.

The AC4 type tamping units are primarily designed for plain line track tamping. With their substantial lateral movement as well as with the swivelling to 90° of the external tamping tools, these units can work in very small radius curves. Mounted onto the B 38 AC narrow gauge tamping machine, these units can wedge the diverging track of a switch up to 1,524 mm from the track axis.

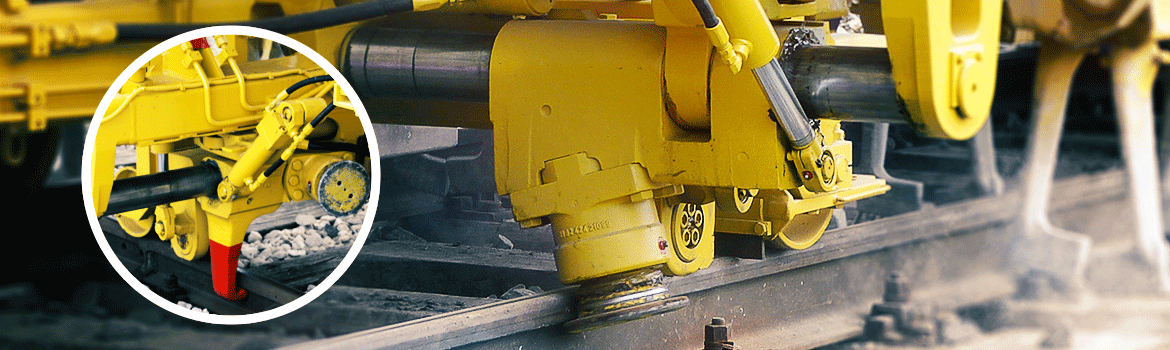

The C type combined clamp has two hooks and two rollers; it is designed to work on all types of switches and crossings as well as on plain line.

The double-roller plain line clamp is fitted on the high-output plain line machines. This clamp has two pairs of rollers and a fishplate detection device.

When working on a switch, the diverging track is usually wedged during the main line tamping process. Sometimes, the lifting and slewing clamp must be assisted by a diverging track lifting device, in particular when handling heavy switches.

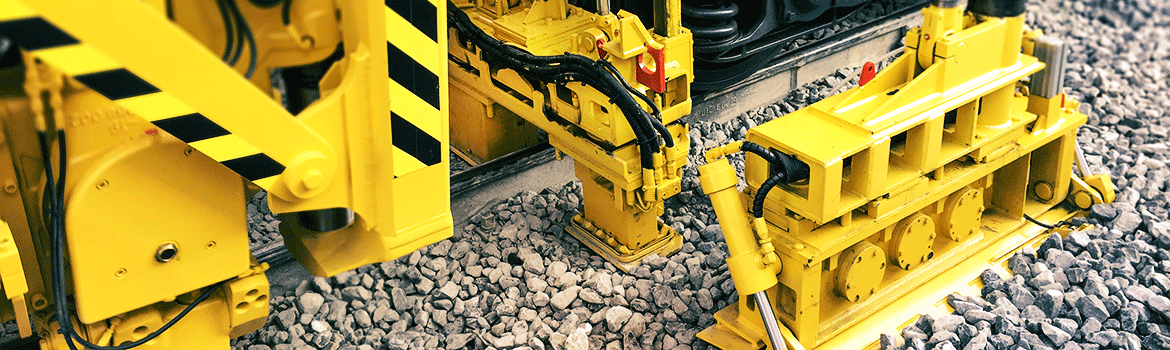

During tamping operations, the lateral and vertical resistance of the track are reduced. A temporary reduction of train running speed is usually applied.

To mitigate these effects, MATISA has developed ballast compaction tools for cribs and shoulders in order to restore a significant part of the lateral and vertical resistance of the track and therefore avoiding speed limitations.

The range of MATISA brushes meets every specific need in terms of rail fastening cleaning and track ballast clearing, with possibility to load the excess of ballast into a hopper. With its wireless remote control, the brush is safe and user-friendly.

Ballast profiling operations are increasingly important during track maintenance process. When tamping, it is essential to have enough ballast to compensate for what has been pushed and compressed under the sleepers. This is of particular importance when the tamping is followed by ballast compaction. After track tamping and perhaps ballast compaction operations, the ploughs remove the excess ballast and profile the ballast shoulders. This also facilitates the track brushing and increases the track lateral resistance.

MATISA MATÉRIEL INDUSTRIEL S.A.